COMPANY NEWS

- Home >> NEWS >> COMPANY NEWS

Product recommendation

Hot News

Contact us

- Tel:+86-0391-3126812

- Phone:+86-15803910375

- Add:The west industrial cluster area of Jiaozuo City, Henan province, China

- E-mail:aefk@aefkchem.com

Application Technology of Polyaluminum Chloride in Waterworks

Raw water enters the waterworks, The raw water with small suspended impurities enters the distribution well (reasonable water distribution, which can reduce, slow down and regulate the water flow during the operation of the water plant) after the initial sedimentation and grid (removing large insoluble impurities), and then flows into the mixer from the distribution well with mixed coagulant to fully mix the agent and water (The model of coagulant shall be selected according to the turbidity of raw water. When the turbidity is greater than 10NTU, drinking water grade polyaluminum chloride or polymeric ferric sulfate can be selected. When the turbidity is lower than 10NTU, the treatment effect of polyaluminum ferric chloride is most significant.) The water after mixing the agent flows into the reaction tank through the mixer (where the small suspended impurities in the raw water will further coagulate and flocculate with the coagulant to form alum), The raw water flows into the sedimentation tank through the reactor (principle of the sedimentation tank: the alum flowers automatically settle to form sludge by their own weight, so as to achieve the purpose of sludge water separation, thus removing small suspended impurities in the water, reducing the turbidity of the raw water, and the settled sludge is pumped from the sedimentation tank to the sludge tank through the sludge pump.) After passing through the sedimentation tank, the filter tank further filters out the suspended solids in the water that are not easy to settle (alum mainly formed by organics and coagulants). After a series of turbidity removal procedures, the water that is further disinfected can flow into the clean water tank (at this time, the water turbidity should be lower than 1 NTU). The water in the clean water tank is then sent to the user through the distribution well to deliver qualified factory water.

Compared with other coagulants, polyaluminum chloride PAC has the following advantages: 1. It has a wide range of applications and wide adaptability to water. 2. It is easy to quickly form large alum flowers and has good precipitation performance. 3. The suitable pH value range is wide (5-9), and the pH value and alkalinity of treated water decrease slightly. 4. When the water temperature is low, the sedimentation effect is still stable. 5. The alkalinity is higher than that of other aluminum salts and iron salts, and the flocculating agent has little effect on equipment erosion.

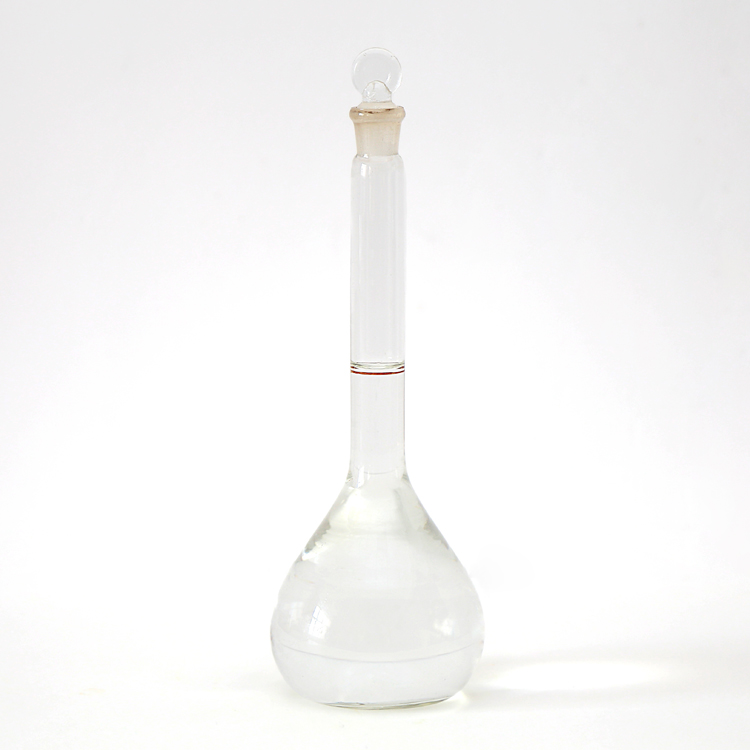

Polyaluminum chloride is an inorganic polymer coagulant. Mainly through the mechanism of compressing the double layer, adsorbing electric neutralization, adsorbing bridging, sediment netting, etc., to destabilize the edema fine suspended particles and colloidal ions, gather, flocculate, coagulate, precipitate, and achieve the purification treatment effect.

Thank you for your attentionHenan aierfuke Chemical Co., Ltd:Focus on water treatment, only for the healthy world! Our company is committed toPolyaluminium chloride、Polyferric sulfateThe R & D, manufacturing and sales of series of water purification materials are willing to create success with our customers and friends.

Chinese

Chinese English

English Russia

Russia