COMPANY NEWS

- Home >> NEWS >> COMPANY NEWS

Product recommendation

Hot News

Contact us

- Tel:+86-0391-3126812

- Phone:+86-15803910375

- Add:The west industrial cluster area of Jiaozuo City, Henan province, China

- E-mail:aefk@aefkchem.com

Characteristics and application of food grade polyaluminum chloride

Food grade polyaluminum chloride is a kind of food grade or milk food grade powdered fine powder made of aluminum hydroxide powder and high-purity hydrochloric acid by spray drying. It is very easy to melt when exposed in the air. In recent years, food grade polyaluminum chloride has replaced aluminum sulfate as a neutral sizing precipitator in the paper industry.

Characteristics of food grade polyaluminum chloride:

1. High Al2O3 content, 29.5%

2. The basicity is low, only 50%, while that of common polyaluminum is about 90%

3. Water insoluble matter is small, only 0.3%, while ordinary polyaluminum has more than 2%

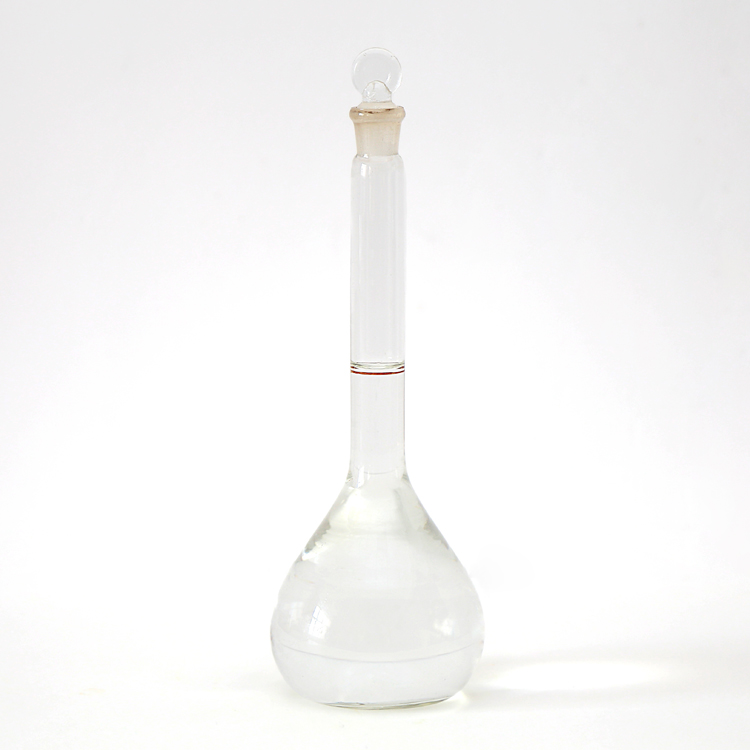

4. The color is white and pure. Except for al+, it does not contain any heavy metals. After the product is turned into water, the aqueous solution is clear and transparent without any color, while the color of ordinary polyaluminum aqueous solution is yellow or brown.

5. Low iron content, easy to dissolve at low temperature.

Product usage:

Food grade polyaluminum chloride can adapt to a pH value range of 5.0-9.0 and a pH value of 6.5-7.6

1. It can be applied to the treatment of river water, lake water and groundwater

2. It can be applied to the treatment of industrial water and industrial circulating water

3. It can be applied to the treatment of wastewater

4. It can be applied to the recovery of coal mine scouring wastewater and porcelain industry wastewater.

5. It can be used in printing plants, printing and dyeing plants, leather factories, breweries, meat processing plants, pharmaceutical plants, paper mills, coal washing, metallurgy, mining areas, as well as the treatment of wastewater containing fluorine, oil and heavy metals.

6. It can be applied to wrinkle prevention of leather and cloth.

7. It can be used for cement setting and mold casting.

8. It can be used for refining pharmaceuticals, glycerin and sugars

9. It can be used as a good catalyst.

10. It can be applied to the bonding of papermaking.

Application method:

According to different water quality and different terrain, the user can determine the dosage by testing the reagent concentration.

1. Liquid products can be put directly or diluted. Solid products need to be dissolved and diluted before putting in. Please determine the dilution water consumption according to the water quality to be treated and the product quantity. The dilution ratio of solid products is 2-20%, and that of liquid products is 5-50% (based on weight).

2. The dosage of liquid products is 3-40 g / T, and that of solid products is 1-15 g / T. the specific dosage is subject to flocculation test and experiment.

3. The acidity of spray drying polyaluminum chloride is lower than that of other inorganic flocculants.

The difference between spray polyaluminum chloride and roller polyaluminum chloride production process:

Spray drying:

Liquid raw materials - pressure filtration - spray tower spray drying - finished products

Drum drying:

Liquid raw materials - placing - drum drying - finished products

Different synthetic costs:

Spray drying products have high stability, wide adaptability to water area, fast hydrolysis speed, strong absorption, fast and large flocculation formation, low turbidity, and strong dehydration. For the same water quality, the amount of spray drying products is smaller than that of other products. Especially for highly polluted water quality, spray drying products only need half of the amount of roller drying products, which not only reduces the labor intensity, but also reduces the cost of customers. In addition, too much spray drying products will not cause pollution, which can avoid accidents and ensure the safety of drinking water quality.

Food grade spray drying polyaluminum chloride is a kind of food grade or milk food grade powdery fine powder processed by spray drying of aluminum hydroxide powder and high-purity hydrochloric acid. It is very easy to melt when exposed in the air and has pure color. After the product is watered, the aqueous solution is clear and transparent without any color, while the color of ordinary polyaluminum aqueous solution is yellow or brown.

6、 Food grade polyaluminum chloride packaging and protection

This product adopts double-layer packaging inside and outside, with plastic bags inside and woven bags outside. 25kg/ bag.

7、 Precautions for food grade polyaluminum chloride:

1. This product is acidic. It is forbidden to store it with alkaline substances (such as bleach, lime, etc.), otherwise the product will be invalid.

2. Solid products are easy to absorb moisture and should be stored in a dry place.

3. Under the condition that the packaging bag is in good condition, the warranty period is one year.

Thank you for your attentionHenan aierfuke Chemical Co., Ltd:Focus on water treatment, only for the healthy world! Our company is committed toPolyaluminium chloride、Polyferric sulfateThe R & D, manufacturing and sales of series of water purification materials are willing to create success with our customers and friends.

Chinese

Chinese English

English Russia

Russia