COMPANY NEWS

- Home >> NEWS >> COMPANY NEWS

Product recommendation

Hot News

Contact us

- Tel:+86-0391-3126812

- Phone:+86-15803910375

- Add:The west industrial cluster area of Jiaozuo City, Henan province, China

- E-mail:aefk@aefkchem.com

Reasonable suggestions on the use of polyaluminum chloride

1、 In order to ensure the rational use of the agent and avoid the waste caused by excessive dosing of the agent, the best dosage shall be determined through the stepped beaker test before dosing, and the dosage meeting the turbidity removal requirements of the lowest dosage shall be the best. The specific experimental process is as follows:

(1. Take five groups of 1000ml water and place them in the six unit coagulation test agitator, or use six 1000ml beakers for the test

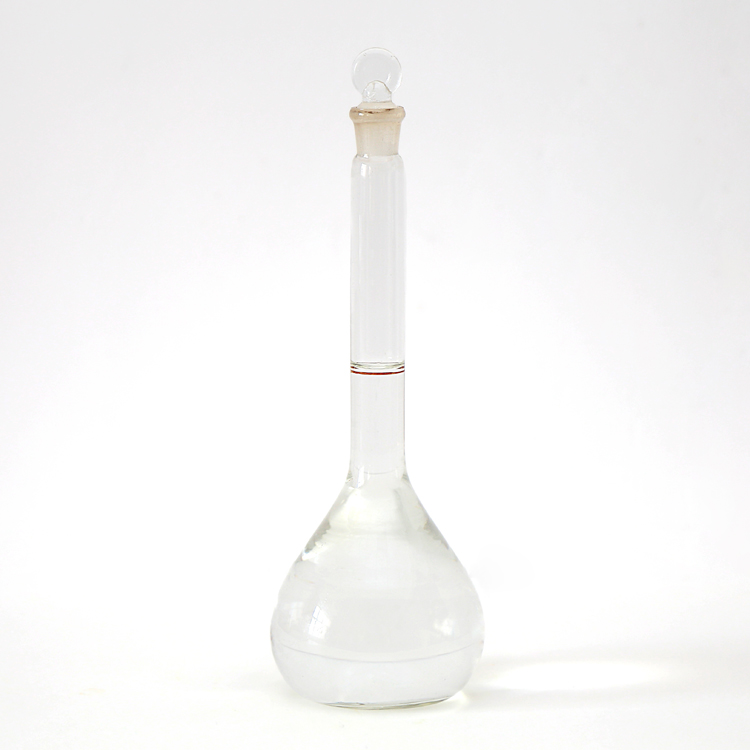

(2. Weigh 1g of polyaluminum chloride and add water to dissolve it. Put it into a volumetric flask with a constant volume of 100ml to prepare a 1% aqueous solution

(3. Add 0.5ml, 1ml, 1.5ml, 2ml, 2.5ml and 3.0ml of polyaluminum chloride to the six groups of raw water respectively for full mixing, and edit the procedures of the coagulation mixer. See the notes for specific setting requirements

(4. After the alum flower is fully settled, take the supernatant and measure the data of the supernatant

(5. If it is determined that the dosage between 0.5ml and 1ml is relatively ideal for water quality treatment, continue to select the dosage of 0.6ml, 0.7ml, 0.8ml and 0.9ml for accurate quantitative experiment

(6. Calculation: each 0.1ml of polyaluminum chloride solution taken in the experiment is equivalent to 1kg of agent in kiloton of water. For example, if 0.5ml of polyaluminum chloride solution is taken for the experiment, the on-site dosage is 5kg of polyaluminum chloride technical agent in kiloton of water

Remarks: hydraulic conditions and alum formation in the three stages of the coagulation process. (1) Coagulation stage: it is a process in which the liquid medicine is injected into the coagulation tank and the raw water is rapidly coagulated to form fine alum in a very short time. At this time, the water body becomes more turbid, which requires that the water flow can produce intense turbulence. In the beaker experiment, it is advisable to stir rapidly (250-300 RPM) for 10-30s, generally not more than 2min. (2) Flocculation stage: it is a process of alum growth and coarsening, requiring appropriate turbulence degree and sufficient residence time (10-15min). In the later stage, a large amount of alum can be observed to gather and slowly sink, forming a clear surface layer. In the beaker experiment, firstly, stir for about 6 minutes at 150 rpm, and then stir for about 4 minutes at 60 rpm until it is suspended. (3) Sedimentation stage: it is a process of flocculate sedimentation in the sedimentation tank, which requires slow water flow. In order to improve efficiency, inclined tube (plate) sedimentation tank is generally used (preferably air flotation method is used to separate flocculates). A large number of coarse alum are blocked by the inclined tube (plate) wall and deposited at the bottom of the tank. The upper water is clear water. The remaining alum with small particle size and low density slowly drops while continuing to collide with each other, The residual turbidity is basically unchanged in the later stage. The beaker test should be conducted at 20-30 rpm, stir slowly for 5 minutes, and then settle for 10 minutes to measure residual turbidity.

2、 Through the beaker test, the best use ratio of dosing agent and raw water is obtained. According to the raw water flow and the controllable dosing flow range capacity of the on-site dosing equipment, the on-site dissolving concentration of the prepared reagent shall not be less than 1.5% based on the alumina concentration

Thank you for your attentionHenan aierfuke Chemical Co., Ltd:Focus on water treatment, only for the healthy world! Our company is committed toPolyaluminium chloride、Polyferric sulfateThe R & D, manufacturing and sales of series of water purification materials are willing to create success with our customers and friends.

Chinese

Chinese English

English Russia

Russia